Two-Speed Transmissions

Two-Speed Transmissions

First and foremost is the knowledge of the company KLOSE-Antriebstechnik, that ensures that the durability of the gearbox in heavy applications does not depend solely on the torque rating. Gearboxes (as well as motors, especially as direct drives) increase their durability when used in this way because of the consideration of shocks that occur due to short-term blocking or hard reversing. These impacts put a particular strain on the shafts in terms of bending, the gearing in terms of breaking, and the rolling elements in the load area in terms of compression.

Part of the KLOSE concept of the gearbox + motor is that their robust housing and all covers are made of thick-walled cast iron. Our models allow casting in gray cast iron (quality EN-GJL-250) or nodular iron (up to quality EN-GJS-600). On request, the components are also available in a welded design or as a combination of both.

According to the requirements in the plants of the rolling mill and metallurgical industry, the gears, shafts and bearings are generously dimensioned to withstand the impacts that occur there. For switching and reversing operations, the safety in relation to the torque is designed to be robust.

Splash lubrication is used to lubricate the gear wheels and high-speed shafts. The roller bearings of the output shaft are lubricated for life via large chambers, but can also be refilled via a grease nipple.

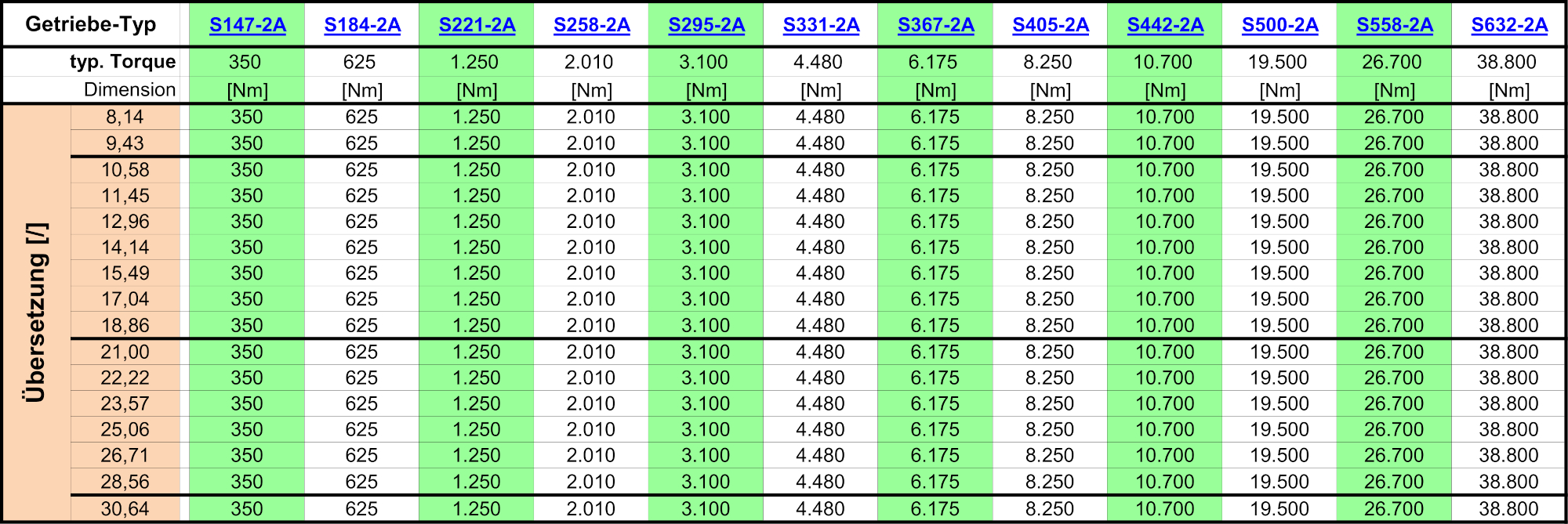

Two-stage KLOSE gears+motors are available with gear ratios of (4.0, which is not included in the table) 8.14 to 30.64 (also not in the table). Standard gear ratios for single-stage gearboxes are listed in the table below. Of course it is possible to realize customer-specific requirements. As an individual manufacturer, the company gemota manufacture any translations (even individual gear pairs) that fit into the existing housing. However, the maximum permissible typical torque specified in the table for each gearbox size remains. In addition, the former company KLOSE has 12 single-stage housing sizes starting with the S147-2A up to the S632-2A. Torques from 350Nm to over 25,000Nm can be achieved.

Designs

The basic version of gears is with foot (B3) and with a solid shaft for the clutch. However, other versions of gears and motors are also possible with interchangeable parts for the KLOSE models. In particular, the slip-on version (H3) with a horizontal motor position, or the version with bevel gear stage (H5) suspended at an angle below should be mentioned. Due to the bevel gear stage as a gear set, the translation naturally expands (in the range of a three-stage gearbox).

It is possible to manufacture these gearboxes with hollow shafts for direct mounting (see explanations for gearboxes with hollow shafts, with their own description).

Other mounting forms, e.g. for vertical assembly, horizontal position or directly flanged gearboxes can be manufactured on customer request. With the large number of housing sizes and the widest range of attachment designs, these gearboxes also offer good conditions for serving as a replacement for gearboxes that are no longer available. The company gemota has specialized in maintaining the existing gearbox connection in a system. As a result, changes in the system (e.g. a new roller table frame) are often not required.

Dimensions

Accessories

Overload Protection

Repeated higher demands on a gearbox and motor due to borderline torques, blockages or very frequent reversing lead to increased temperatures, especially in the motor.

The safest protection against destructive overloading is therefore monitoring the temperature development in the motor itself. See thermal winding protection for the motors.

Tachos, Encoders

If the drive needs to record the current speed of the material on the roller table, a tachometer can be mounted on a second shaft end if required. If the material is to be positioned in a targeted manner on the roller table, a pulse generator is attached. Advantageously, however, the speedometer / encoder is on the motor

Brakes

If the material is to be positioned and held with a gear + motor, a brake can also be attached on request. An additional shaft end is also used for this purpose. Drum brakes or spring-loaded disc brakes are used. Advantageously, however, the brake is located on the motor in order to increase the force even more through the translation of the gearbox