Special Constructions

General

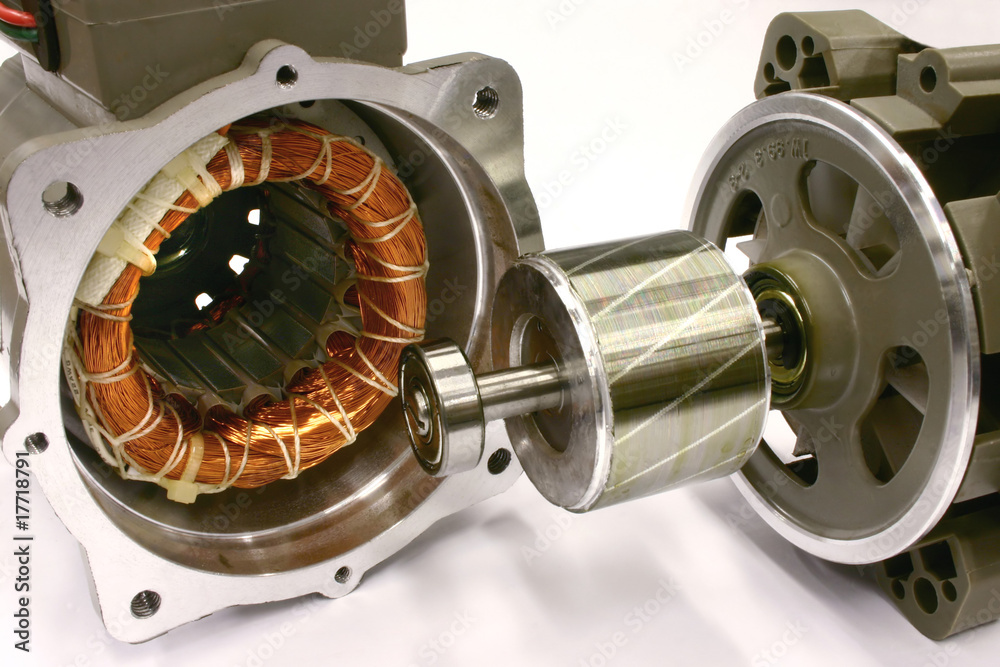

It was possible to show which gearboxes and which motors belong to the scope of production of the former company KLOSE Antriebstechnik. In addition, it was highlighted how space-saving the combination of gearbox and motor turns out to be. But special designs often require the production of gearboxes and motors according to customer requirements. The result is a special design with individual production and targeted design of all components.

We would like to give two examples in the following:

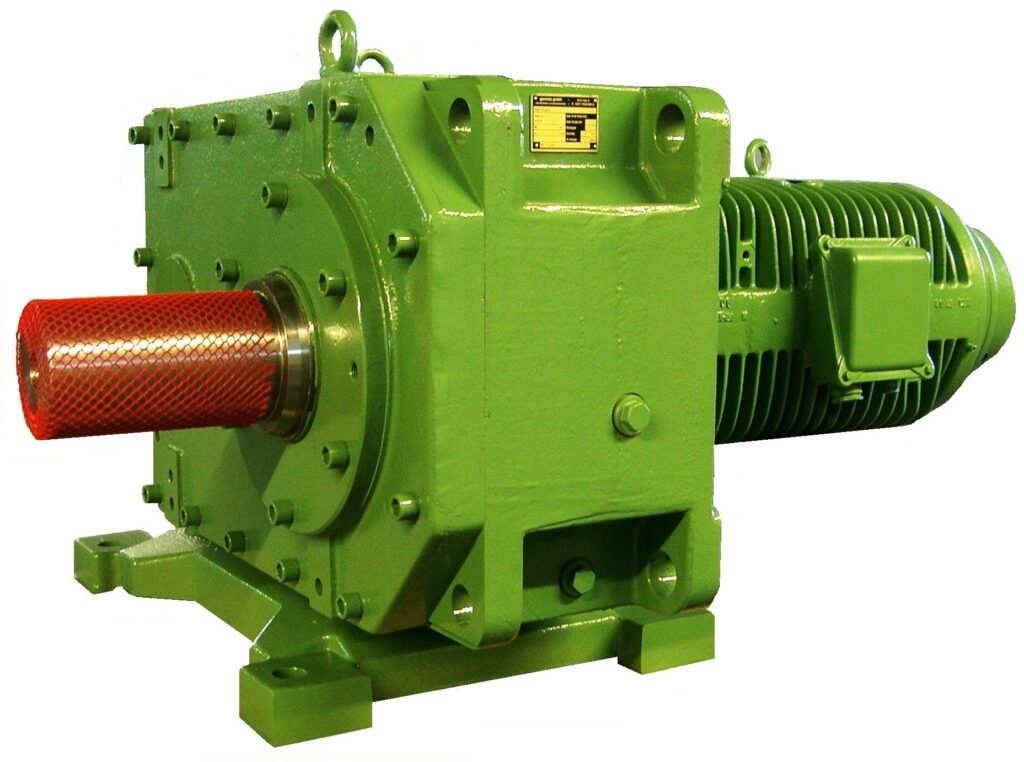

Transmissions with ratios greater than 100

The heavy flange for coupling the engine to the gearbox also opens up the possibility of adding additional space here. Although the motor shaft remains as part of the first gear stage, this space is given an additional gear stage through additional gearing. This increases the overall ratio to over 100:1. With a relatively small motor, the transmission could generate sufficient torque to convey slabs with a total weight of over 60 tons at low casting speeds. The gearbox and motor shown in the side position is prepared for coupling via cardan shaft. The transmission has three stages and has a nominal torque of over 12,000[Nm] and there is also a brake on the motor for targeted material placement.

The lantern wheel as a gearbox with several output shafts

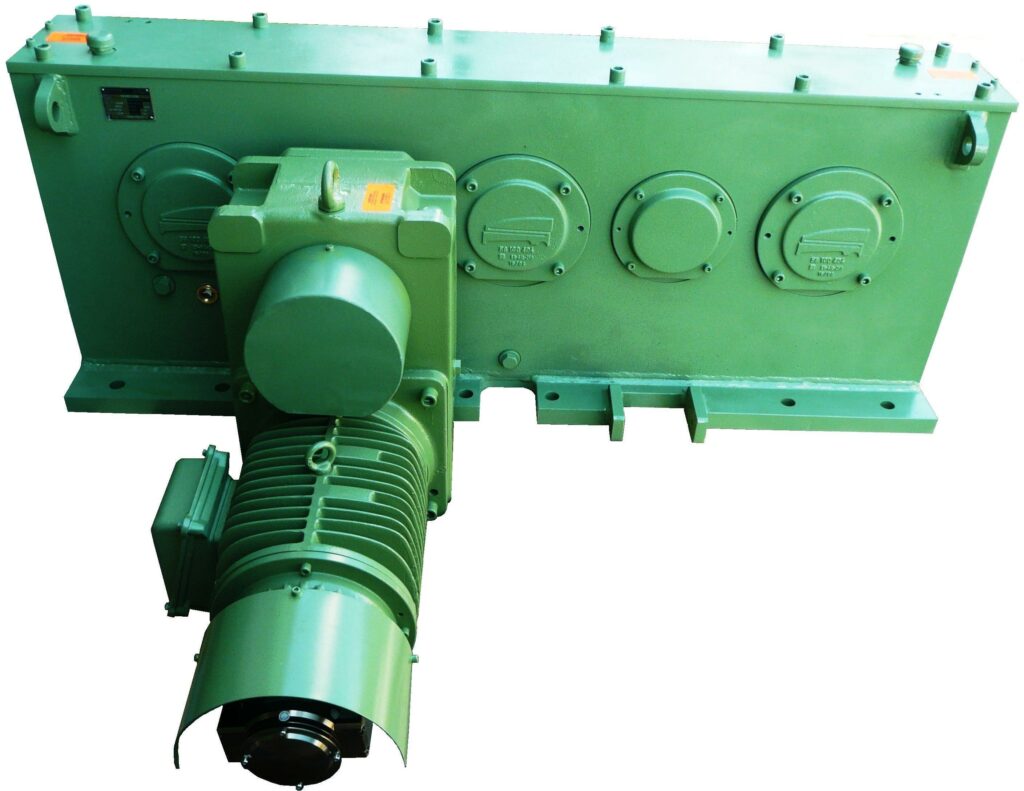

For the drive of a continuous furnace, or specifically in the area of the stand rollers of a rolling mill, several rollers must run synchronously. There is often not enough space, even for the short KLOSE-type gearbox and motor. The drive of several rollers now requires motion transmission from an input drive that is not in the middle. When it comes to excessive loads in the rolling mill industry, a belt drive or a chain is not an option. A transfer case with large spur gears and an intermediate shaft for the same direction of rotation is more advantageous. The diameters of the wheel and intermediate shaft must be coordinated so that the distance between the rollers is precisely met. A representation of such a machine is shown in the attachment.

The drive is a roller table gear + motor KLOSE type S258-2A / KDRG20G22-6 which is pushed onto the transfer case via its hollow shaft. The six-pole motor can be operated with a frequency of approx. 5[Hz] to over 50[Hz]. It also has a speedometer for speed control. The entire gearbox has a ratio of over 120:1.

For a furnace roller table, a wide range of plate thicknesses can be moved continuously and electrically controlled through the annealing furnace, from creep speed to “normal” strip speed.